Insight into our dynamic project portfolio

Guiding projects through strategic innovation

The Global Center for Water Technology (GCWT) houses 25 individual project labs, all with a unique focus in their respective project category. As a whole, we work to spark technology creation by evaluating current technologies and developing Technology Roadmaps to shape impactful projects that deliver real value.

Project Categories:

- Arizona Department of Environmental Quality

- Atmospheric Water and Harvesting

- Brine Management

- Food and Fuels

- Water Management

- Water Treatment for People and Industry

Once the Technology Roadmap is created and projects are established, a Needs-Approaches-Benefits-Competition (NABC) framework is implemented. This aligns project inventions with user needs, develops novel approaches, creates measurable benefits, and strives to outperform existing technologies. An entrepreneurial approach like this encourages our research staff to think innovatively and plan for the future of their project.

Explore the tiles below to discover how GCWT’s diverse projects are transforming water technology for communities and industries!

Arizona Department of Environmental Quality

Regeneration Assessment of PFAS-laden Anion Exchange Resin from Treatment of PFAS-Containing Groundwater in Arizona

Principal Investigator: Treavor Boyer

Ion exchange (IX) treatment is considered one of the most effective technologies for PFAS removal from water. Despite its effectiveness, there is a need to define when regenerable IX treatment makes sense for drinking water applications in Arizona and to identify the best practices in site-specific assessment of regenerable IX treatment. The approach for this project is to evaluate the regeneration efficiency of IX treatment for PFAS, and to identify key components for implementing and costing a regenerable IX treatment system. The expected benefits of this project include new performance data, new cost estimates, and improved understanding of regenerable IX treatment for PFAS-impacted water resources in Arizona, which will support ADEQ in reviewing and permitting regenerable IX treatment systems and support public water systems in designing and operating the systems.

Passive Technologies to Remediate Mining Waste Stream

Principal Investigator: Anca Delgado

Co-Investigator: Otak Conroy-Ben

Nearly 120 miles of surface water in Arizona are contaminated with mining waste containing heavy metals and acid discharge. Traditional technologies such as limestone channels increase alkalinity and are effective at removing certain metals but add hardness to an already impaired water. We are evaluating passive and active remediation technologies for stream restoration under harsh environmental conditions. Combinations of limestone, lime, soda ash, and biochar are assessed for metal removal, recovery, and water quality. Sulfate-reducing bioreactors are designed for metal-sulfide precipitation and metal recovery, either as the main heavy metal treatment or as a final polishing reactor. These technologies will help reach the goals of protecting Arizona’s surface waters through metal remediation and co-recovery.

Technology Assessment of Brine Management in Arizona with Consideration of Deep Well Injection

Principal Investigator: Peter Fox

Arizona faces an urgent need for sustainable brine management strategies as desalination and industrial water use grow, straining limited disposal options and challenging state regulators. Our project directly addresses this by conducting a comprehensive assessment of innovative technologies, from high-recovery desalination and mineral extraction to the feasibility of deep well injection, creating integrated solutions tailored for Arizona’s unique brine chemistries. Preliminary economic analysis demonstrates the clear benefit of deep well injection (DWI) as compared to evaporation ponds. The primary benefit of this research is providing the Arizona Department of Environmental Quality (ADEQ) with a data-driven framework to develop effective regulations, enhancing water security through greater water recovery, and creating new economic opportunities by turning brine into a valuable resource.

Predictive Modeling of Arizona Groundwater Quality Using Transfer Learning

Principal Investigator: Tianfang Xu

Arizona’s reliance on groundwater demands proactive quality management, yet comprehensive monitoring of contaminants across over 100,000 domestic wells and small drinking water systems is prohibitively expensive and logistically challenging. To overcome this barrier, our project leverages transfer learning, integrating sparse local data with national/global datasets to train machine learning models that predict contaminant concentrations spatially and temporally using physiographic, climatic, hydrologic, and anthropogenic drivers. By enabling cost-effective identification of at-risk aquifers, forecasting noncompliance risks, and optimizing sampling strategies, this project aims to empower ADEQ to allocate resources efficiently while safeguarding water quality.

Cesspool and Unpermitted OWTF Identification to Enhance Rural Arizona Sustainability

Principal Investigator: Ruijie Zeng

Contaminant effluents from Onsite wastewater treatment facilities (OWTFs), such as cesspools and septic tanks, cause environmental concerns and health risks, especially is rural areas. Missing information on the number and location of OWTF limits state agency Arizona Department of Environmental Quality (ADEQ)’s capacity to mitigate the impacts of OWTF. This study, funded by GCWT, collocates with ADEQ and local communities to develop spatial analytics to identify OWTF inventory in Arizona rural communities and assess the environmental risks associated with OWTF effluents. Outcomes from this project will help state agency better allocate resources for OWTF replacement and upgrade and improve environmental and public health in vulnerable communities.

Atmospheric Water and Harvesting

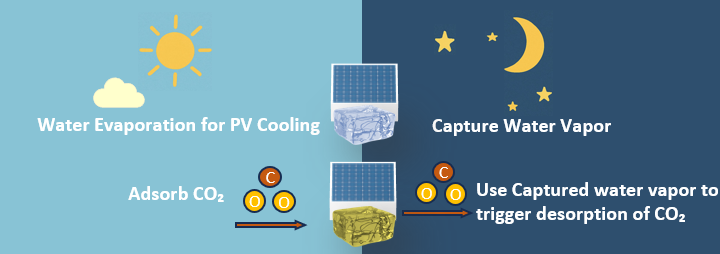

Development of Atmospheric Water Harvesting Hydrogels for Solar Panel Cooling and Atmospheric Water Capture

Principal Investigator: Lenore Dai

To meet the rising demand for sustainable water sourcing and efficient passive cooling in solar photovoltaic (PV) systems, this project develops zwitterionic atmospheric water harvesting (AWH) hydrogels with dual functionality for both AWH and direct air carbon dioxide capture (DACC). The polymer is a porous, crosslinked hydrogel network of [2-(Methacryloyloxy)ethyl]dimethyl-(3-sulfopropyl)ammonium hydroxide (DMAPS), integrated with hygroscopic salts. This architecture leverages the salt-in effect to minimize salt leakage while maintaining high moisture uptake over multiple cycles. Performance is further enhanced by incorporating N-isopropylacrylamide (NIPAm) to accelerate drying and introducing hydroxide ions to enable moisture-responsive CO₂ capture. Together, these features support a multifunctional platform that provides evaporative surface cooling for solar panels, supplies condensed water as a supplemental resource, and captures CO₂ through moisture swings. With its low-cost fabrication, scalable potential, and environmental responsiveness, the hydrogel system offers a promising solution for integrated energy and sustainability applications.

Water Management in Direct Air Capture Technology

Principal Investigator: Matt Green

This project aims to develop a water-efficient direct air capture (DAC) technology to address the need for carbon dioxide (CO2) removal, given rising global temperatures, and the need for water security in Arizona’s arid climate. Our approach involves creating a bench-scale prototype, made to capture ~5 kg CO2/day, integrating innovative water recovery technologies to reduce the practical steam ratio to 1 or even 0, and developing a virtual process model to guide energy efficiency. Our goal is to scale up our technology for wider implementation. By minimizing water use in our water-stressed region and leveraging scalable, low-cost materials, our work advances DAC as a necessary negative emission technology.

Ultrasound-Enhanced Desorption for Atmospheric Water Capture

Principal Investigator: Patrick Phelan

Co-Investigator: Shahnwaz Sinha

Over 2.1 billion people globally face water scarcity, with Arizona and other Southwestern U.S. states among the hardest hit due to chronic droughts, climate change, and a recent 20% reduction in Colorado River water allocations. To address this, our team is developing an ultrasound-enhanced atmospheric water harvesting device that uses silica gel-based desiccants coated onto high-specific-area Triply Periodic Minimal Surface (TPMS) geometries to accelerate water capture and release, particularly in arid conditions (RH < 30%). The system incorporates polarity-switchable thermoelectric coolers (TECs) to enable continuous operation and efficient adsorption and desorption. This innovation supports clean, localized freshwater generation without greenhouse gas emissions, offering a scalable solution for water-stressed regions. Compared to commercial and traditional desiccants, our coated desiccants exhibit significantly faster adsorption/desorption kinetics, providing a clear advantage in both performance speed and system efficiency.

Heat Management in Atmospheric Water Extraction for the Air Refinery

Principal Investigator: Ellen Stechel

Co-Investigator: Ivan Ermanoski & James Miller

Water and energy are the two critical inputs for hydrogen- and synthetic-fuel complexes, yet in desert regions these plants gain lasting community and regulatory support only if they spare local aquifers and the electric grid. We are developing an air-to-water module that uses the plant’s own exhausted heat—augmented by variable airflow, passive radiative cooling, and on-site thermal and water storage—to harvest humidity instead of importing water, while drawing only minimal fan power. An optimizer treats liquid- or solid-sorbent loops and hour-by-hour desert temperature-humidity data as design variables, sizing fans, exchangers, beds, and tanks to minimize three externals: purchased water, purchased electricity, and heat rejected to the sky. The resulting add-on closes the water loop for any high-temperature process at a small fraction of total plant cost and removes a major social and political barrier to scaling clean-fuel production in arid regions.

Brine Management

Industrial and Brackish Groundwater Brine Disposal and Permeate Reuse

Principal Investigator: Paul Westerhoff

Co-Investigators: Mariana Bertoni & Tiezheng Tong

Arizona is now a global semiconductor manufacturing hub despite extensive drought conditions, and faces significant sustainability challenges due to the industry’s high demand for ultrapure water and complex wastewater management. As the design of modern semiconductor chips reaches sizes of below 10 nm, the impact of minute contamination becomes increasingly vital for the final quality of the devices. By working with our industry partners, we will identify what intrinsic defects of the semiconductor material and extrinsic defects of the ultrapure water system used throughout the manufacturing process have the potential to impact the quality of the semiconductor material. Through the use of state-of-the-art techniques that address the location, composition, chemical state, band structure, and nearest neighbor environment of defects, we will quantify the impact of these chemical impurities on material properties.

Separations and Treatment Platforms for Saline and Hypersaline Water

Principal Investigator: Matt Green

This project develops zwitterion-modified polysulfone membranes for energy-efficient desalination to address Arizona’s water future by treating saline feedstocks with reduced energy and maintenance costs. The approach involves synthesizing and characterizing membranes with high zwitterion content to enhance water permeance and salt rejection, using pervaporation to minimize energy demands, and incorporating chemical crosslinking to improve mechanical stability. To optimize energy efficiency and recyclability, we incorporate mechanistic studies on biofouling and scaling, alongside process modeling. The benefits of this are sustainable access to potable water, reduced water waste and reduced desalination energy costs.

Evaluation of Potential for Mitigating Evaporative Water Loss in Large-Scale Industrial Manufacturing in the Phoenix Area Using Ground-Coupled Heat Pump Systems

Principal Investigator: Nariman Mahabadi

Co-Investigators: Edward Kavazanjian

In Arizona’s rapidly growing industrial sector, a single semiconductor plant can lose up to 5 million gallons of water per day through evaporative cooling —an unsustainable strain on the region’s already limited water supply. With extreme heat and prolonged drought intensifying across the state, there is an urgent need for water-efficient cooling solutions that work in arid, high-temperature environments like Maricopa County. This project develops Engineered Geo-Cooling systems specifically designed for Arizona’s climate. These systems collect heat from industrial buildings and transfer it into the ground through closed-loop pipes, using high-conductivity geomaterials to enhance thermal exchange, eliminating the need for evaporative water loss. The team combines advanced simulation, lab-scale testing, and material innovation to engineer efficient, site-adapted ground-coupled heat pump (GCHP) systems. Engineered Geo-Cooling has the potential to dramatically reduce water use and cut energy consumption by up to 72%, providing a scalable, low-maintenance, and long-lasting cooling solution for Arizona’s industrial infrastructure. This technology directly supports the state’s water resilience and climate adaptation goals. Unlike conventional cooling towers—which are incompatible with Arizona’s water challenges—Engineered Geo-Cooling offers a transformative, dry-climate-ready alternative that could become the new standard for sustainable industrial cooling across the Southwest.

Mitigating Silica Scaling in Low-Salt-Rejection Reverse Osmosis for Minimal Liquid Discharge of Municipal or Industrial Brine-Waste Streams

Principal Investigator: Tiezheng Tong

Silica scaling is the main constraint that limits the water recovery of desalination and brine treatment. This project aims to develop novel mitigation strategies to control silica scaling in low-salt-rejection reverse osmosis (LSRRO) as an emerging technology towards minimal liquid discharge (MLD), reducing the cost and energy consumption of membrane-based desalination and wastewater treatment towards a circular water economy. It will benefit multiple industrial sectors where membrane desalination and hypersaline brine treatment are needed.

Food and Fuels

Anticipatory Life Cycle Approach to Improve the Environmental Performance of Engineered Food System for Phosphorus Recovery and CO2 Utilization

Principal Investigator: Treavor Boyer

Co-Investigator: Dwarak Ravikumar

Agricultural operations in arid regions use significant amounts of water and commercially produced phosphorus and nitrogen for fertilizer that pollute air, water, and landscapes. There is a need to reduce the use of limited resources in conventional agriculture, develop new engineered food systems that integrate resource recovery, and improve the overall sustainability of agriculture and food systems. The approach of this project is to develop new life-cycle models that evaluate the environmental impacts of resource recovery on conventional agriculture and evaluate the environmental trade-offs between conventional agriculture and new engineered food systems. The expected benefits of this project include identifying new approaches to wastewater management that achieve water and nutrient recovery for use in agriculture, and new approaches of recovering waste phosphorus and nitrogen for the creation of food-grade protein.

Nanobubbles for Enhancing Hydroponic Crops

Principal Investigator: Sergi Segura-Garcia

Co-Investigator: Jesús Morón López

Employing Water Resources for Waste Stream Valorization

Principal Investigator: YenJung Sean Lai

Co-Investigator: Bruce Rittman

The principles of the circular economy (CE) open up opportunities for pollutant reuse rather than just removal. Water reuse becomes essential for reducing water demand and capital costs for many industries. The benefits of water reuse are amplified when pollutants are transformed into valorized products from the waste streams. This double benefit is particularly effective in Arizona, which faces serious and growing water scarcity.

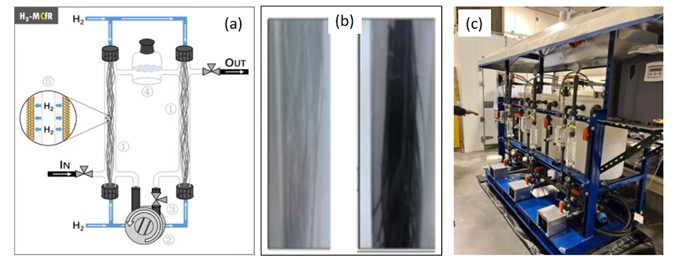

Our strategy has two integrated components (as seen in the image above): a unit for photo-electric water splitting (left) that generates H2 gas, and a membrane-based catalytic and biotic processes (right) that utilized the H2 and exhaust CO2 gas streams to generate hydrocarbons, such as formic acid, acetate, and ethanol. By valorizing water and CO2, this approach can lead to cost-effective means to achieve zero-discharge goals.

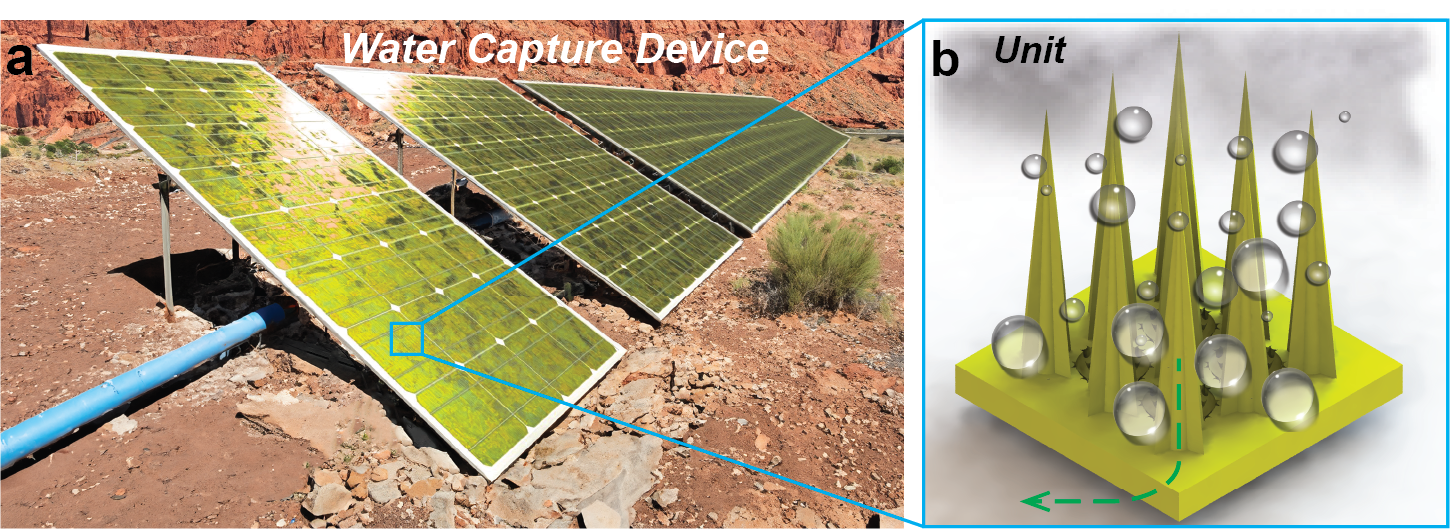

Atmospheric Water Harvesting for Green Hydrogen Production

Principal Investigator: Meng Tao

This project develops a 6-kW water electrolysis system for clean hydrogen production, the water is captured from the air. The electric power for electrolysis and water capture is derived from solar panels. Therefore, the system requires no man-made supplies. It is suited for remote regions such as Native American homes and desert villages, where supplying power and water for clean hydrogen production can be challenging. It can also be used as an autonomous system for clean hydrogen production, without human intervention!

Water Management

Bioinspired Bifunctional Structures for Zero-Energy Atmospheric Water Capture

Principal Investigator: Xiangfan Chen

Co-Investigator: Chao Ma

Access to handwashing facilities is vital for preventing the spread of infectious diseases, safeguarding public health, and maintaining hygiene in both routine and emergency contexts. However, handwashing generates significant amounts of greywater that is challenging to fully reclaim for reuse. Our solution focuses on developing an energy-efficient greywater treatment technology tailored for handwashing applications. This approach reduces treatment costs, promotes broader use of recycled greywater, and mitigates health risks.

Quantifying the Water Footprint and Water Losses of Evaporative Cooling Towers in Commercial Buildings in Arizona

Principal Investigator: Dwarak Ravikumar

Co-Investigator: Saurav Kumar

The increased deployment of water-based evaporative cooling towers to meet cooling needs of industrial and commercial facilities can exacerbate the water stress in Arizona. Despite these concerns, there exists no robust method to estimate the water footprint and losses from cooling towers currently installed in Arizona. Our research combines artificial intelligence, computer vision and physics-based models to determine the geospatial spread of cooling towers in Arizona and estimate their water footprint and losses. The findings from our research will help water planners and the city and state government to plan and minimize the water requirements to meet the future commercial cooling needs through a mix of air-based conventional cooling technologies and cooling towers

Evaluation of the Membrane Catalyst-film Reactor for PFAS Destruction in Water

Principal Investigator: Bruce Rittman

Co-Investigator:YenJung Sean Lai

Given more stringent PFAS regulations, many drinking-water utilities soon must implement PFAS treatment, but currently available technologies only remove PFAS from water into an adsorbent medium (e.g., granular activated carbon (GAC)) or concentrate the contaminants into a brine stream (e.g., reverse-osmosis (RO)). The spent media or the concentrated brine require additional and expensive treatment prior to safe disposal. Treatment technologies that can fully mineralize PFAS into carbon dioxide and fluoride ion are a pressing need. The membrane catalytic film reactor (MCfR; as shown in Figure 1) has demonstrated outstanding defluorination performance for the range of PFAS. This gives the MCfR a large advantage over conventional techniques because it destroys PFAS, not just removes it. Also, the MCfR can be implemented at ambient temperature without extreme inputs of energy.

Establishing Scalable, Cost-Effective Manufacturing for Bulk Production of High-Performance Atmospheric Water Harvesting MOFs

Principal Investigator: Seth Tongay

There is an ever-growing demand for accessible water across all sectors, particularly for high-quality water that meets drinking and manufacturing requirements. In order to ensure these needs are met going forward, it will be necessary to establish new sources of water generation. One promising solution that has garnered significant interest is that of using metal-organic framework (MOF) materials for capturing ambient water from the air, a concept commonly known as atmospheric water harvesting (AWH). However, while great progress has been made in the development of water harvesting MOFs, their widespread adoption into the AWH space has been slowed due to the complexities and costs associated with bringing production to scale while maintaining the desirable efficacy.

The goal of this project is to overcome these challenges through the design of a manufacturing process that allows for the affordable production of various MOFs with consistent quality to support production levels ranging from academic to industrial requirements. Additionally, this project aims to further maximize the impact of these MOFs by implementing green synthesis methods. By concentrating on providing a production process that is cost-effective and quality-preserving, those seeking to use MOFs for AWH and other resource stewardship applications can focus on their implementation goals.

Water Treatment for People and Industry

Sustainable Treatment of Wastewaters for Reuse in Arizona

Principal Investigator: Peter Lammers

Co-Investigator: Shuguang Deng

Treatment and reuse of wastewater is needed to meet demand for water in the arid Southwestern U.S. Our project focuses on anaerobic digestor wastewater (centrate) which comprises only 1% of the total water volume at treatment facilities but carries up to 25% of the nitrogen and phosphorus. Currently, centrate is recycled to the front of the plant, creating a parasitic load that lowers plant efficiency, increases energy costs and greenhouse gas emissions. Direct treatment of centrate using extremophilic algae being tested at the City of Phoenix 23rd Avenue plant is expected to reduce GHG emissions by >50%. Using metabolic engineering tools, we are developing new algae strains that are able to produce hydrogen gas to lower treatment costs associated with sludge and centrate management. Diversion of centrate to algae treatment will expand water treatment capacity by removal of the parasitic load on the plant.

Selective Removal of Low Molecular Weight Molecules from Industrial Wastewater

Principal Investigator: Mary Laura Lind

Co-Investigator: Eileen Seo

Novel Depolymerizable Membranes for Stimuli-Responsive and Reversible Water Remediation

Principal Investigator: Timothy Long

Co-Investigator: Jeffrey Self

Our team delivers a technology platform for removal of ions from water using the delivery of light together with high surface area functional fiber optics. Our platform integrates commercially viable polymeric materials with next generation functionalization of photo-responsive surfaces for low energy consumption at room temperature. The coupling of novel materials, optical properties, and advanced processing delivers a versatile water remediation platform that selectively and reversibly binds calcium ions, thus delivering purified water from small-scale households to large-scale manufacturing sites.

Greywater Treatment with Aerophilic Surfaces

Principal Investigator: Chao Ma

Co-Investigator: Xiangfan Chen

Access to handwashing facilities is vital for preventing the spread of infectious diseases, safeguarding public health, and maintaining hygiene in both routine and emergency contexts. However, handwashing generates significant amounts of greywater that is challenging to fully reclaim for reuse. Our solution focuses on developing an energy-efficient greywater treatment technology tailored for handwashing applications. This approach reduces treatment costs, promotes broader use of recycled greywater, and mitigates health risks.